Climate change has become so evident that responsibility of each and every individual is so accountable. Amid such situation, a science teacher Marchis Moirangthem did a exemplary work to save forest from destruction by producing eco-friendly charcoal.

The impact of climate change reaches every nook and corner of the world. To prevent disastrous impact of environment degradation, it is so essence to think climate change issue globally and act locally.

Manipur as one of the North Eastern states having cold weather in winter, felling down of trees for charcoal production is also one of the reason to destruct and damage forest and environment.

Being a nature lover and with sense of responsibility to prevent this mother earth from further deterioration due to human greed, Marchis Moirangthem has taken up initiative of making eco-friendly charcoal. His contribution might be small yet valuable considering the changing climatic condition.

Revolution in the making

A school teacher by profession from last 10 years, Marchis Moirangthem from Ningthoukhong which is around 35 km from Imphal under Bishnupur district had innovated an idea of making eco-friendly charcoal from rice husk, waste paper or cardboard and wheat flour. His new endeavour had humble beginning from past three months. But with growing of demand from public, it has become a challenging task for Marchis to meet the demand. Nevertheless, he is putting all effort with his limited resources and manpower to fulfil the demand of public.

Sharing his thought that how his new venture was started, Marchis told to India Today NE that massive deforestation in the state has deteriorated environment to a great extent. With the concern and strong desire to save mother earth from climate change impact cause by anthropogenic factor, idea of making eco-friendly charcoal has come up in his mind.

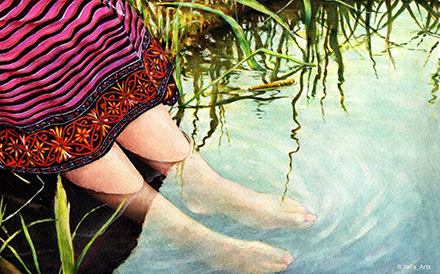

“Manipur is a land where one can enjoy pleasant weather condition. But as impact of climate change reaches each and every corner of the world, Manipur has lost its such perfect weather condition has been gradually. Being a nature lover, I keep on thinking that on what way I can contribute to save this mother earth,”Marchis expressed.

Marchis started his new venture with limited resources since the day the idea has clicked in his mind. His financial condition is not and this has become a major challenging factor. But what is most impressing his that he continues crafting eco-friendly charcoal using all possible way and means.

“I encounter lot of challenges and difficulties in doing this new venture due to shortage of money. As such I couldn’t produce my product in large scale. I hope I can produce this eco-friendly charcoal in good amount had adequate money is invested. So far, I couldn’t hire any staff as I am not in a position to provide their salary or wages. Therefore, with the help of my family member and some friends I manage to run this new venture with great effort and hurdles,” he said.

Making this deforestation free charcoal seems to be time consumable and need lot of hard work. But with the objective to stop deforestation for purpose of making charcoal, Marchis try to make his eco-friendly charcoal at low cost by selling it at rate of Rs 50 per Kg.

While explaining the process of making eco-friendly charcoal, he said that most of the step involve in making eco-friendly charcoal is handiwork. First step of making this environment friendly charcoal is to carbonised the rice husk for at least eight hours. The carbonisation is done by heating rice husk indirectly using bitumen drum as a furnace. The heat produce from drum will transfer to rice husk and carbonated by keeping it fro at least eight hours.

He further said that Carbonised rice husk has to be cool down by sprinkling water. This will be followed by grinding the carbonised rice husk into powder. The grind carbonised rice husk will mix with waste paper which is already soaked in plain water for 24 hours. This mixture will add wheat flour as a binding agent. d After this, the fully mixed item will be compressed in a compressor. This compressed mixture will dry in sun for two to three days. To reduce the drying up period, solar reflector developed by himself is being used.

One person is capable to make 20 kg of charcoal in a day. So, if manpower is increase, large amount of charcoal can be produced, he added.

He also pointed out that normal process of directly burning down the rice husk can produce lot of harmful gases such as nitrogen oxide, silicon dioxide, sulphur dioxide. But the process of indirectly heating the rice husk using furnace releases least amount of hazardous gases.

Stating about equipment he used, he said that compressor in making charcoal is designed by himself but it was set up by welder who happens to be his friends. They are Jyoti Basu and Thoiba.

Being a school teacher by profession, Marchis is finding difficulties in time management. But the constant support from his younger brother, he can successfully continue his venture.

In a plea for support, Marches earnestly requests Government intervention, recognizing it as a pivotal factor in elevating production. He underscores the urgency of this appeal, emphasizing the broader objective: “I seek investment to enhance production capacity and replace the prevailing trend of wood-based charcoal production with the sustainable approach of utilizing paper waste and rice husk.”

His venture not only contributes positively to the local community but also sets a compelling example for a greener and more sustainable future. The Manipur Government’s endorsement and support for Marches Moirangthem’s environmentally conscious enterprise would not only validate his efforts but also contribute significantly to broader initiatives aimed at preserving our planet for future generations.